We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

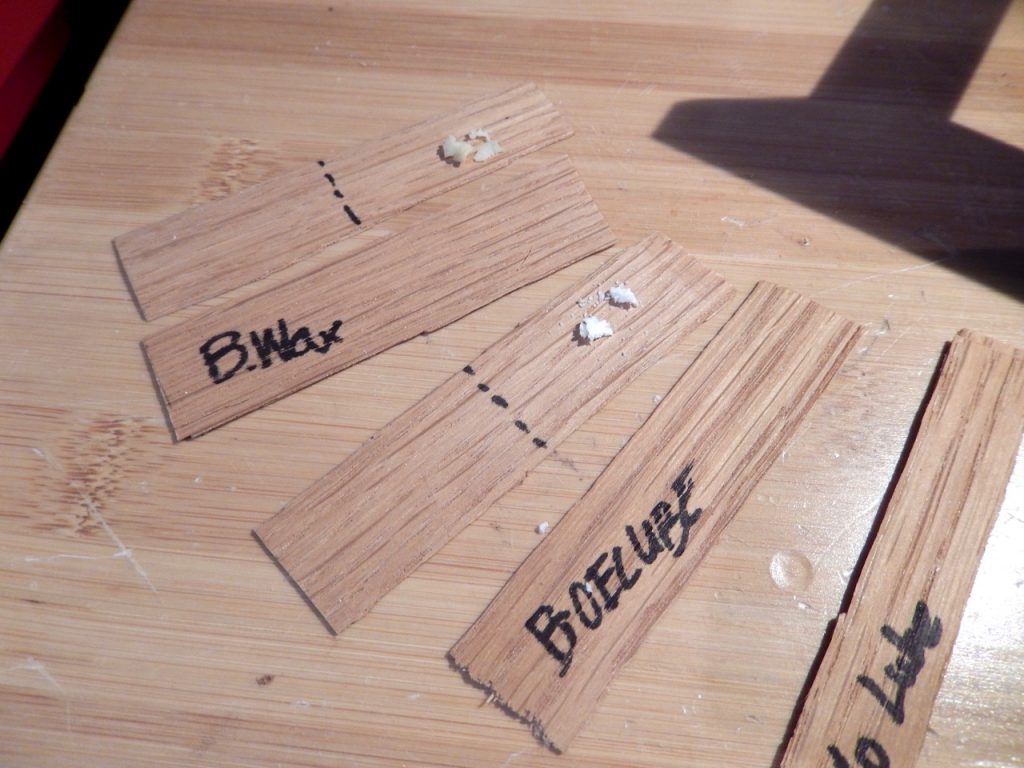

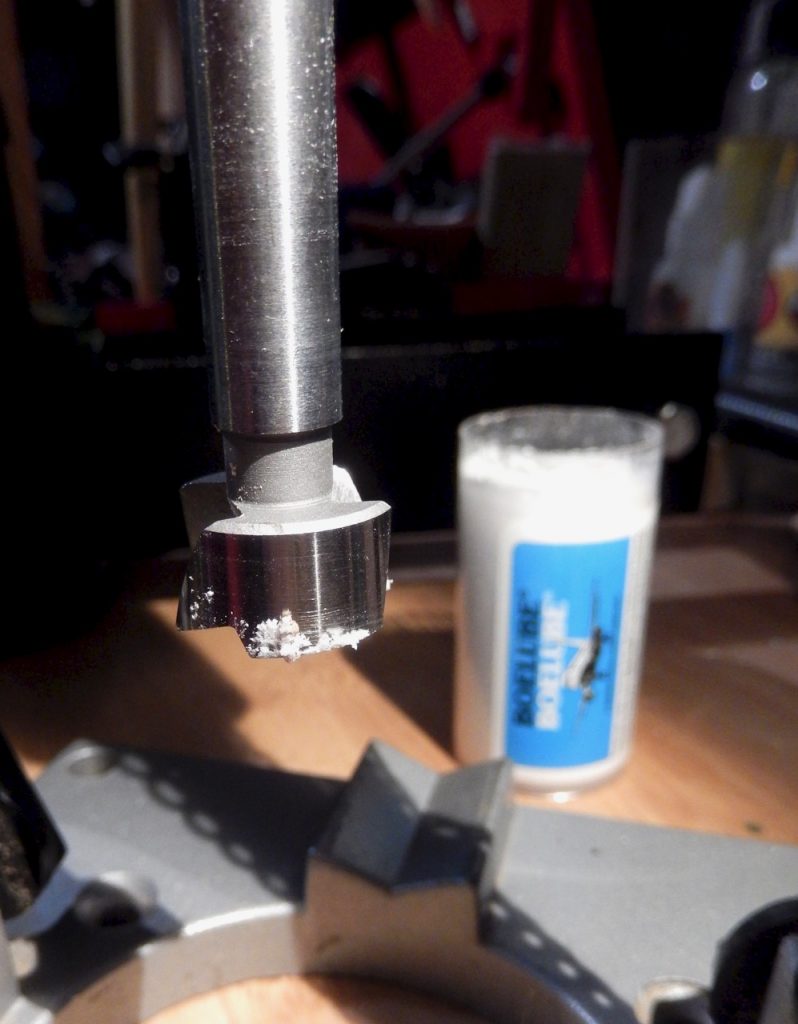

Boelube comes as flaky wax, oil, or paste. The one I got was the wax-like material.

Most lubricants are associated with oil, wax and grease, substances that are hard to remove from wooden surfaces. When drilling wide or long holes in wood, especially when you later need to glue a dowel into this hole, you wouldn’t want to have any residues of grease or wax to jeopardize the adhesion. But there is a way to have your cake and eat it too. I recently discovered a product that helps me drill in awkward situations, reduce friction and noise, and yet is “water-based”, and thus will not hinder the gluing process. This material was invented by the Boeing Company and is sold under license, carrying the brand name BOELUBE. I bought the Boelube in a powder-wax from Amazon and use it on Forstner bits, twist bits, plane soles, and in any applications that require lubrication of wooden objects. I also use it when drilling metals.

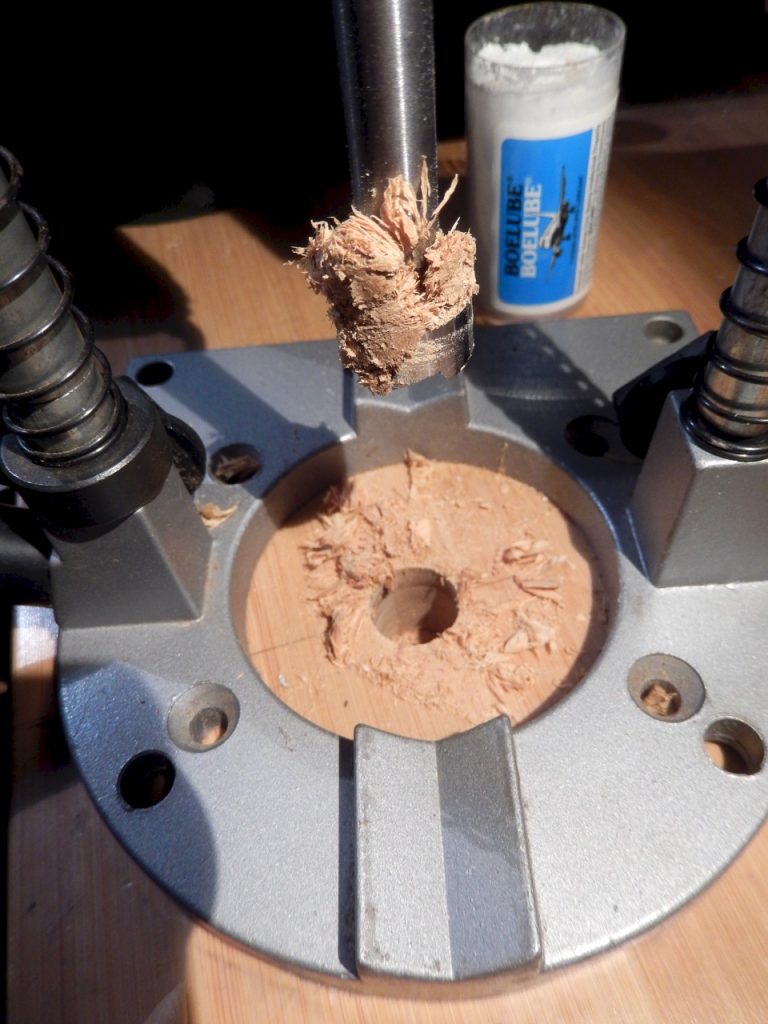

Putting a little bit of Boelube on a Forstner bit will reduce friction and noise during drilling tough materials, such as in the case of my solid bamboo bench top.

Not surprisingly, I found that Boelube is quite helpful when I need to install wooden screws, and especially those made of brass. For years I have used paste wax, but the problem with paste wax is that, if for some reason you have stripped the wood (by over-tightening the screw) you’ll find that it is hard to rebuild the inner threads because of the embedded wax. Trying to fill up the hole by gluing in a segment from toothpick for instance, may or may not succeed because the wax might inhibit this. However, a water-based lube will not cause that degree of trouble and will allow you to rehabilitate the grabbing capabilities of the hole with ease.

Not surprisingly, I found that Boelube is quite helpful when I need to install wooden screws, and especially those made of brass. For years I have used paste wax, but the problem with paste wax is that, if for some reason you have stripped the wood (by over-tightening the screw) you’ll find that it is hard to rebuild the inner threads because of the embedded wax. Trying to fill up the hole by gluing in a segment from toothpick for instance, may or may not succeed because the wax might inhibit this. However, a water-based lube will not cause that degree of trouble and will allow you to rehabilitate the grabbing capabilities of the hole with ease.

Another great advantage of this product is that it doesn’t attract dust and will not build a cake of oily film as petroleum-based lubricants do.

How did I conclude that the Boelube is not negating water based glues? (at least not as much as traditional wax)

To check the Boelube ability to dissolve in water, and thus allow glue to reach the wood fibers I conducted a simple comparison experiment. My plan was to apply paste wax (in this case, Butchers Block Wax), and Boelube on identical pieces of wood, rub the excess, and then glue them to scraps that were not treated with any lube. I also planned on gluing together two pieces of scarps that were not treated with wax, to serve as a control.

1. Putting identical quantities of lube matter on the oak veneer.

2. Cleaning the excess.

3. Rubbing glue.

4. After the glue dries I pried the two pieces of veneer.

Notice that in both the control and the Boelube pieces the glue held on and the wood fibers broke. Only in the case of the paste Butcher Block wax the pieces of veneer separated.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.