We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Read part 1 here and read part 3 here.

As I was about to finish the rack, I began contemplating what would be the best way to hang it on the pegboard. One of the most abundant pegboard hooks in my arsenal is a simple angled hook that fits into a pegboard hole and send a cantilever arm upward at 75 or so degrees.

My first mounting attempt was to incorporate two of these hooks at each end of the rack.

Drilling an angled hole in the rack could have sufficed but I decided to nest the hook flash with the back of the rack, so I gouged out a shallow canal too.

Just before I was about to hang the rack a new idea came to my mind. What if I install a few magnets on the rack to maximize its utility, allowing some additional tools to be hang on it.

Luckily I have a few of Lee Valley’s rare-earth magnet (Cup & Washer Sets) . I have used them over the years and was happy with the way they carry load. To install the magnet one need to drill a counterbore hole in the wood, then affix the cup using a screw and lastly drop the magnet in place. In theory this is easy but in practice it might take some tinkering with.

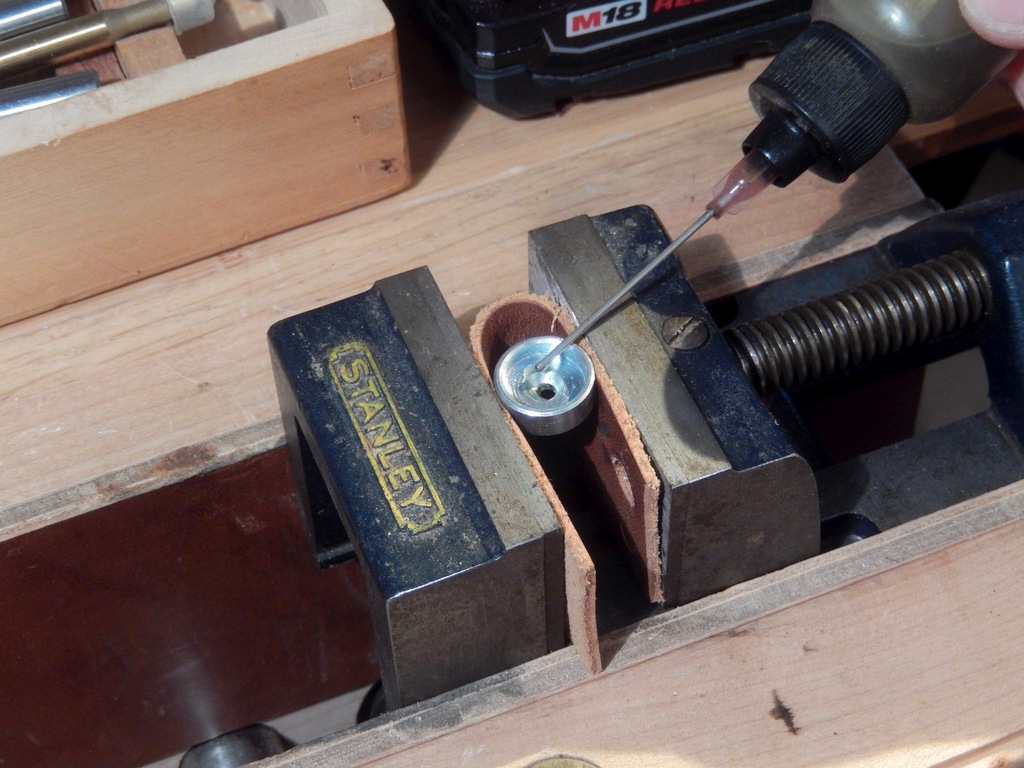

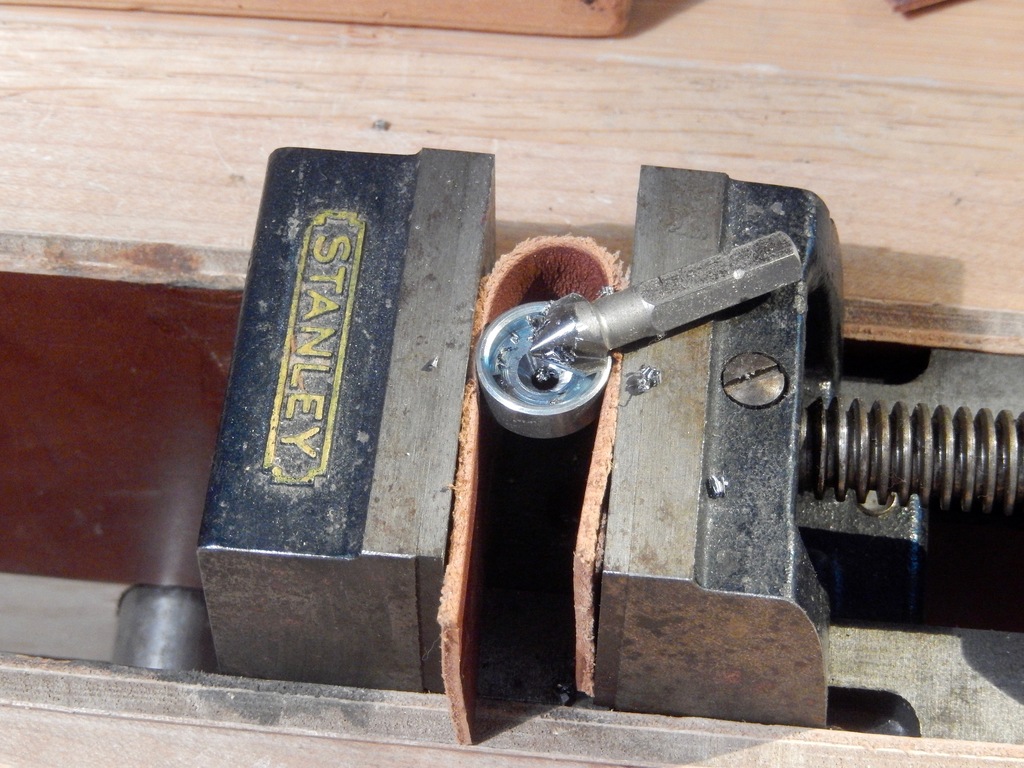

First I learned that in order to allow the mounting screw of my choice to nest flash with the surface I had to countersink the cup beyond the factory’s countersinking specs. So I held the cup in a small Toolmaker’s Vise and enlarged the countersink.

As I was trying to screw in the cup I found out (not for the first time) that the factory made countersink is just too small for the screw I chosen for the job.

To re-countersink the hole hold the cup in a small vise, add some oil and countersink it with a countersink for metal.

The other common issue with installing the cup is that after setting both the cup and the magnet you may conclude that the cup is too proud (or perhaps too recessed) and need to be adjusted a tad deeper (or shimmed up higher), but alas, you already dropped in the magnet in place. The manufacturer’s instructions in this case are: “If you plan on removing the magnet and cup, first file a slot down the sidewalls for an access point to pry out the magnet.”

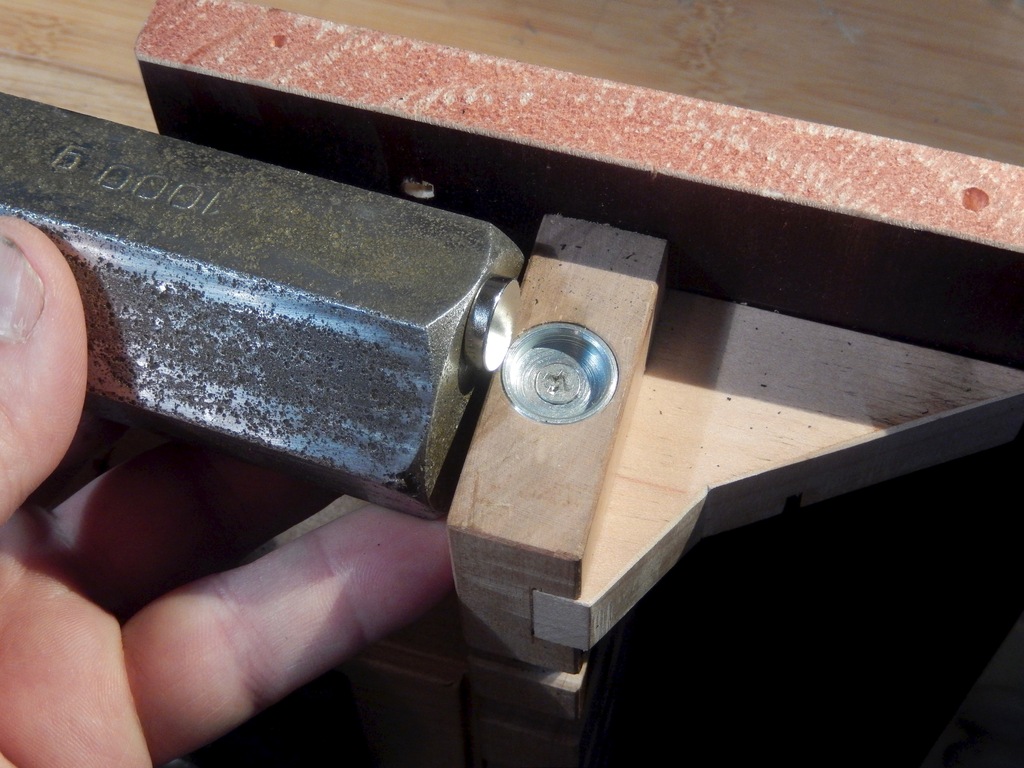

After re-countersinking the hole the screw sit flush with the surface.

I found out that you can attract the magnet and pop it out by using a heavy hammer of compatible heavy-mass steel/iron object, which will save you the trouble of filing a slot. After I popped the magnet, I unscrewed and removed the cup and then deepening the counterbore. Following this I reinstalled the cup and dropped in the magnet.

A cup and a magnet duo has enough attraction power to hold a saw, a marking knife and even a light weight chisels or knife.

When I gave the rack a test run everything looked and felt fine. Although it looked fine and worked fine, I was not completely happy. My first concern was safety, and in particular avoiding cuts from the exposed chisel tips. The other concern was that since the rack is hanged on the front of the cabinet’s door, wouldn’t it be stronger and easier to anchor it via screws from the backside of the pegboard?

I will show how I addressed both these issues on my next blog entry.

Read part 1 here and read part 3 here.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.