We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

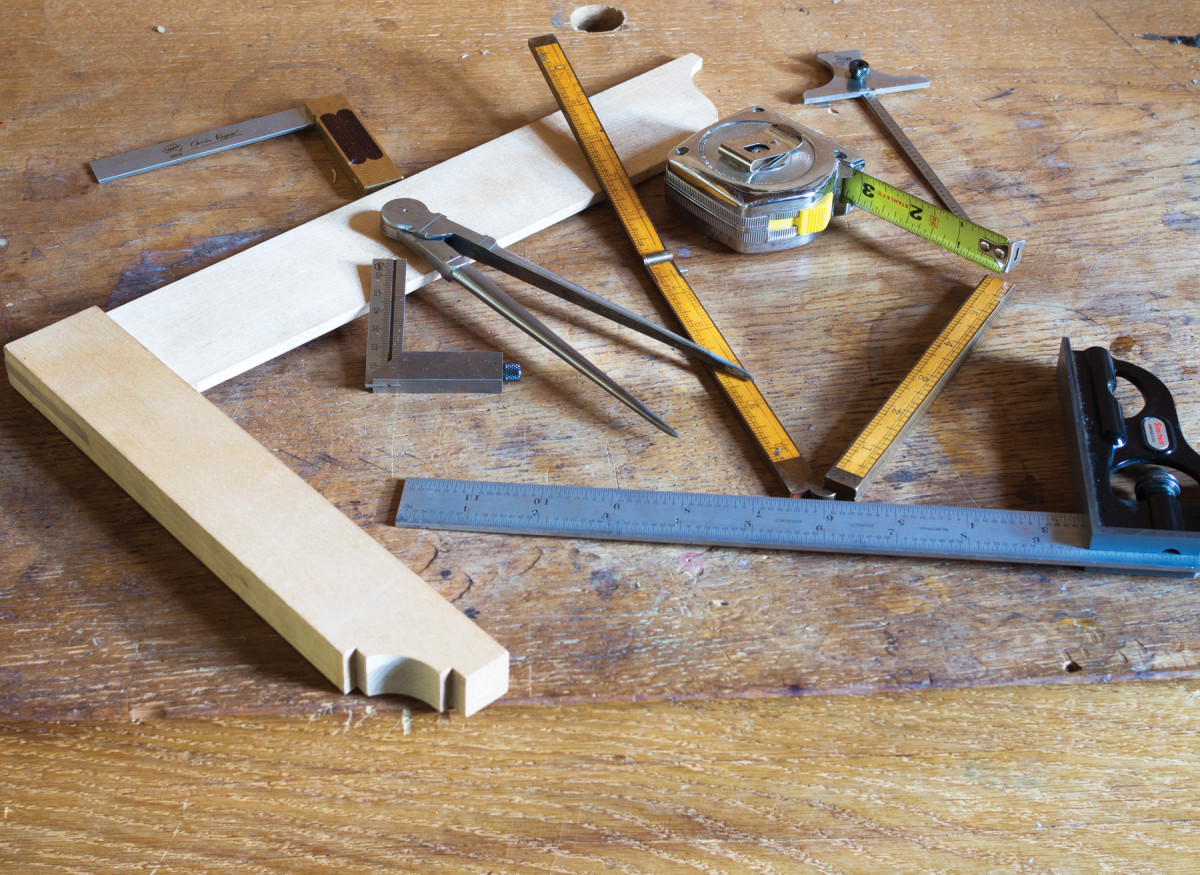

It’s not the tools. Wondering how to step up your game with better measurement? Chances are, you’ve already got the right tools – but they may not be the ones you reach for.

You’re measuring wrong, and making it more difficult to do good work.

If the title has you expecting high-tech procedures or suggestions for expensive measurement gear that’ll get you closer to Angstrom-level measurements, then let me disappoint you quite thoroughly before paragraph one ends. This isn’t that kind of party.

That shouldn’t suggest that I’m going to advocate anything remotely resembling a lazy, “close-enough” approach, though. Not even a little. In fact, I think the most common source of problems in the shop is in taking and working with measurements – sloppy doesn’t cut it.

What I am going to suggest is that there are a lot of misconceptions about the whole idea of “precision” that are not doing anyone any favors – misconceptions that are thoroughly tangled up with an inherited approach to measurement that could really use a head-on evaluation.

Before getting to any concrete suggestions, though, you’ll have to grant me a bit of latitude in the trail we take to get there. Is my route the best one, or just the result of adult ADHD? Probably both – but that’s your call. It’s the only way I know to make the case properly.

Two Ends of the Spectrum: Both Wrong

Divide and conquer. I dragged this old toolbox carcase out to fit it for a bank of drawers.

On either end of any good argument about precision in woodworking, there are two persistent myths. They can be hard to spot once the hazy logic and armies of straw men start to show up, but in my experience, they’re always there.

■ Myth 1: Precision is like clamps, money or paper towels – you can never have too much.

Tricky division? I want eight equal drawers, so if the opening is a light 27-3⁄8″, how big should each drawer be?

It’s easy to see the appeal of this notion. If precision is good, then more precision is better. And once that’s settled, then obviously precision should be gathered and hoarded at all costs.

But it’s a woefully shallow take on things – a cost-benefit analysis that ignores cost. Precision, like most things, carries a price – usually paid in time, money or effort – all finite resources being eaten up for more refined capabilities. And, like all such transactions, the smart take is to find the “sweet spot” where you’re getting results you need, but not too far past the point of diminishing returns.

That sweet spot varies spectacularly with the type of work, obviously. The sweet spot for yard fencing and luthiery are nowhere near each other. Nonetheless, the approach is the same.

■ Myth 2: Anything more precise than 1⁄8” or so is a waste of time; the material is going to move more than that every time the seasons change.

It’s not a number. A pair of large dividers gets me the answer faster than I can write the calculations on paper. How many inches? Who cares. (Get an idea for how this technique works here, all you’re doing is adjusting the divider until it walks the distance exactly. That’s your drawer measurement)

Phrases like this are the reason I mutter under my breath. One reason, anyway.

We all know wood moves, but that doesn’t mean it sets the agenda. We have several millennia of hard-won collective knowledge about all manner of ways to accommodate, mitigate and work with wood movement. The collection of techniques for attaching bits of wood to one another is so central and unique to woodworking, it has its own name: joinery. Joinery is why woodworking is not bricklaying, and why woodworking texts are longer than the phrase “use glue.”

If that doesn’t appeal, or seem worthwhile, then woodworking seems an odd way to spend your time.

The difference between perfectly fit dovetails that remain tight all year and a self-destructing drawer doesn’t lie in being sloppy with measurement. It’s in knowing and using the techniques of joinery.

You Keep Using That Word…

Is the opening square? Makeshift pinch rod (two sticks with beveled tips and a clamp) tell me everything I need to know faster, and more accurately, than any protractor, square or laser will.

If we’re going to get serious about delving into measurement, then sooner or later we’ve got to address the biggest source of confusion in the whole mess – which is what, exactly, “precision” is.

The problem is not that we don’t know what precision is. The real problem is that our understandings aren’t compatible. In fact, I’ve noticed that even one person’s working definition seems to shift radically from one context to the next. I am not, of course, talking about either you or me here – but if we look at everyone else, it’s clear as day that their understanding of “precision” is shockingly imprecise.

At around this point, someone as astute as you and I can’t help but notice that in use “precision” seems to look less and less like a word than like some sort of foreign spy with a sophisticated cloaking device. Which explains a few things.

In semiotics (the study of “signs,” which is popular with academic pinheads and indiscriminate pseudo-intellectual toolmakers) such words are called “floating signifiers.” Floating signifiers are usually so familiar and so self-evident that it’s a feat of effort to even notice their most interesting characteristic – which is a glaring lack of specific meaning.

In use, they’re like a bizarro-world version of communication. Rather than convey a meaning that we interpret and respond to, they trigger a response, and their vague meaning shifts to whatever best reinforces the response.

So before we move on, we need to pin down a precise definition for our terminology if we want to get anywhere. In this case, we can look to metrology (the study of measurement, which is popular with a different batch of pinheads, who refuse to eat lunch with the semiotics pinheads) for its very specific definitions.

In metrology, precision is always defined alongside the term “accuracy.” It’s hard to have any clarity on one without the other. The common explanation uses the analogy of target practice. Imagine you’re competing, and you shoot five bullets, arrows or spitballs at a bullseye target.

Accuracy is about how close to the bullseye any specific shot hits.

Precision, on the other hand, is about how closely together your shots landed; it’s your “grouping.”

Precision in this sense has nothing to do with accuracy – it doesn’t even make sense for any single shot. You need a group of shots to say anything about the precision of your shots. It’s a measure of your consistency.

Bringing it back to measurement: Imagine making a photocopy of a ruler at half-scale. If you measure a 6″-wide board with it, that ruler would read as 12″. So, your half-sized ruler is ridiculously inaccurate. If you were careful in how you used it, though, and got very consistent measurements every time, then it would still be a precise ruler, consistent with itself.

So, now that we have made the distinction between precision (consistency) and accuracy (um – accuracy) – which one is more important in the shop?

Two Approaches to Taking Measurements

Still no numbers. I transfer my divider calculation to a marking gauge, and mark the drawer face for the right height.

This is where things get interesting, and it’s what most woodworkers should think about when they consider measurement. There are two different approaches to the question, and most of us default to the wrong one.

1. Standardized Units

In the modern world, most of us take up woodworking without considering how we measure things. We start with a system we were indoctrinated into through our entire education, in our workplaces and everything we are surrounded by.

In that system, all length measurements are in universal standardized units. Inches, feet, millimeters – all of those units are standard, and it’s the only way most of us have ever dealt with measurement. It’s an approach that is so universal, it’s a huge stretch just to realize that it IS an approach.

There is a good reason for the absolute dominance of standardized measurement in the global manufacturing world. That system is absolutely critical to every industry on the planet.

But in the lone woodworker’s shop, where the entire path from plans to finished piece never leaves, those standards don’t apply a lot of the time.

2. Measuring Without Units

Drawer, meet carcase. The simplest route is the best: drawer width is as easy as holding the face in place and marking it. The result is a perfect press-fit measurement.

This can seem silly. Talking about “direct measurement” can feel like slapping a name on the simplest thing in the world and pretending it’s a discovery. Simply putting a board next to the space it needs to fit, and then marking that length… it hardly seems like a “system.” It sounds like common sense.

The problem, though, is that most people have an ingrained bias to prefer standardized measurements. Many times, I’ve watched someone use dividers to get a direct measurement and then turn around and double-check things with a ruler “just to be safe.”

If you look back at your experiences, how many “new” techniques have you picked up that involved direct reading in preference to standardized measures? Marking gauges, bevel gauges, story sticks, pinch rods – even the use of the sliding head on a combination square? Now consider how many times you’ve dismissed some form of direct marking in favor of measuring with some graduated standard.

That’s what I thought. Here’s the fix.

Some Rules of Thumb

Many parts, one line. Gang-cutting is a form of direct measurement, too.

Not all measurements are created equal, of course. It would be impossible (and boring) to give an exhaustive list of techniques here. What I can do is give you some things you might find on a poster for the Angry Inch Society.

■ Use contact, not vision. Eyes lie. Any time you visually align something, or even just read a scale, the chances for error go up. Direct physical contact is more accurate and precise.

■ Math is not your friend. Not only do calculations open the door to errors, those errors are often cumulative. Dividers are one secret weapon. There are plenty of strategies to avoid having to do math. Find them and use them.

■ Don’t “transfer” a measurement from one device to another when you don’t need to. In other words, if you plan to scribe a given measurement with a marking gauge then use the gauge to take the measurement if you can.

■ Have a system. All else being equal, I always use the top or left of a piece as my reference surface (sometimes called the “datum”). Often you don’t get the luxury of picking, but when you do get to pick, pick the same way every time.

■ Don’t use more instruments than you need. Having a dozen squares of different lengths is great – but for any given measurement-to-marking process, don’t mix them.

■ No more steps than necessary. This is the most general, and most important, guideline I can pass along. Measurement is the first step in a layout chain that usually ends with marking something else. Every single step in between is a potential for error and degraded accuracy – so make the chain as short as possible.

Don’t mix your measuring tools. How many squares should you have? One per measurement. Don’t use two (or three) tools to measure one thing. And don’t “transfer” measurements among them.

This isn’t a screed against standardized measurements – or against expensive, high-tolerance metrology instruments. I am a toolmaker, after all. I routinely work to thousandth-of-an-inch tolerances, and smaller on occasion. I have more surface plates than I care to admit, and an affection for Swiss test indicators that is unhealthy.

It is, however, the best case I can make that most of us have our default modes completely backwards.

For the one-person shop, direct measurement is superior in almost every way. It’s simpler, cheaper, more consistent/precise and it sidesteps the most common and serious errors in any shop.

When you have to – and you will – shift to standardized measurement, do it. We live in the real world, and most projects will have at least one or two places where avoiding standardized measures is silly. The height of your tables need to match the other furniture in your house – plus furniture you might not own yet.

And if you order hardware, you can’t send a story stick with your credit card info.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.