We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Japanese Dozuki Saws

A terrific precision saw can cost as little as $25.

By Tom Caspar

What’s the point of a handsaw in a shop full of power tools? If the saw doesn’t cut worth a darn, not much at all. But if it’s a Japanese dozuki saw, you’ll wonder how you ever got along without one. Dozukis are hand-powered cutting machines. They cost an average of $40 to $50. Handsaws go where machines can’t. Sometimes a cut is awkward or time-consuming to set up with a machine, but a good handsaw can do it lickety-split. I used to be a big fan of English-style handsaws, but when I tried a dozuki saw, there was no turning back.Let’s first take a look at the differences between Japanese and Western joinery saws and what makes Japanese saws so good. Then we’ll look at the general types of dozuki saws, and finally recommend some specific saws to buy.

Japanese and Western saws

All Japanese saws cut on the pull stroke; Western saws, as we all know, cut on the push stroke. Once you’ve made the switch, you’ll find the pull stroke quite natural. It has two overwhelming benefits: following a line is much easier, and that makes sawing far less fatiguing, both physically and mentally. Japanese saws designed for cutting joints are called dozuki saws. (The word dozuki refers to the shoulder of a tenon.) Dozuki blades are very thin because they’re pulled taut as you cut. All dozuki saws have a blade stiffener, or spine, that runs most of the length of the blade and into the handle. The handle itself is always long, narrow and generally wrapped with rattan to improve its grip. It can be held with one hand or with two for additional control. The entire saw is very lightweight. A Western-style saw for cutting joints also has a blade stiffener, or back, and so it’s usually referred to as a backsaw. A backsaw’s blade must be relatively thick so it doesn’t buckle when pushed. The backsaw’s handle can be an elaborately shaped grip or a simple turned knob. Both styles are held with one hand. Most backsaws are heavier than dozuki saws. The dozuki saw’s thin blade cuts an extremely narrow kerf (Photo 1). A backsaw’s kerf is often twice as wide, or more. That means you’re removing half as much wood with a dozuki and exerting half as much effort. Your muscles can relax, so you can concentrate on following the line (Photo 2). A backsaw requires much more effort and mental anguish, particularly when it’s dull. Dozuki saws stay sharp for a very long time. Most saws have tempered teeth so hard they can’t be sharpened with a file. When the saw gets dull, you pop in a new blade. Backsaws generally have softer teeth. When they get dull, you can file and set them yourself. Backsaw teeth are so small, however, that sharpening can be a real challenge. Most woodworkers don’t bother and simply continue to use a dull saw, with disappointing results.

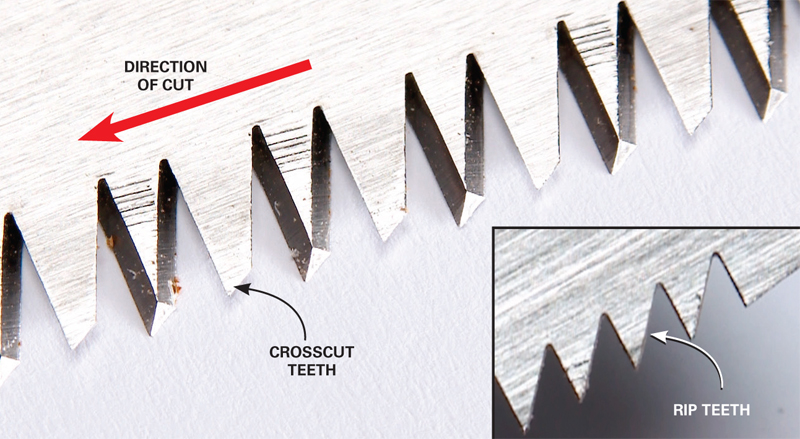

Dozuki teeth: crosscut and rip

Dozuki saws excel at sawing across the grain (Photo 3). Most dozuki saws in American catalogs have crosscut teeth. Crosscut dozukis also cut quite well with the grain. Rip cuts for tenons and dovetails are no problem as long as they don’t go more than an inch deep. (The saw may bind if your cut isn’t dead straight.) In fact, it’s when cutting dovetails that most woodworkers really fall in love with their dozuki saws. Dozuki saws designed specifically for ripping are just making their way to our shores. These saws are similar in most ways to their crosscut cousins, but their teeth are shaped differently (Photo 4). Rip-cut saws work across the grain fairly well, too. They’re more expensive than crosscut saws. Our favorite rip-cut dozuki is a new model from Lee Valley, leevalley.com, 800-871-8158, #60T04.04. Its blade is not replaceable and cannot be resharpened, however. If you’ve never used a dozuki, start with a standard crosscut saw. It’s better for general-purpose work than a rip-cut saw. A crosscut saw is less aggressive, so learning to use one is easier.

Replaceable blades

Most dozuki saws have replaceable blades (Photo 5). A second blade usually costs about half as much as the saw itself. Each replacement blade is specifically made to fit only one brand of saw. When you find a saw you like, it’s a good idea to buy a second blade before the first gets dull. Reserve the fresh blade for the cuts that really matter.

Teeth per inch

Dozuki saws have three different ranges of teeth size. Most saws have 22 to 27 teeth per inch (tpi). They work well in pieces from 1/8 in. to 1 in. thick. Saws with large teeth have 13 to 18 tpi. They cut very aggressively and are best suited for stock that’s at least 3/4 in. thick. Getting started on the first cut, without bouncing, takes some practice. A few dozuki saws have incredibly small teeth (32 tpi). They’re extremely easy to start without bouncing. They’re not for beginners, however, because the blades are so thin and flexible. Our favorite is a 6-in. saw from Bridge City Tools, bridgecitytools.com, 800-253-3332, #1101-171.

Blade length

Dozuki saws have blades of two different lengths: short (6 to 8 in.) or long (9-1/2 to 10-1/2 in.). Length doesn’t determine the size of the teeth. Two blades of different lengths by the same maker usually have the same number of teeth per inch. A saw with a long blade is best for most work. You can take a long stroke and cut fairly deep each time you pull the saw. Short blades are best suited for small work or shallow cuts, when fewer strokes are needed.Click any image to view a larger version. 1. A Japanese dozuki saw is ideal for precision work because it’s so easy to control. It cuts on the pull stroke. An English-style backsaw, of course, is just the opposite; it cuts on the push stroke. The dozuki saw blade is very thin and makes a much narrower kerf. The less wood you remove, the easier it is to guide the saw.

1. A Japanese dozuki saw is ideal for precision work because it’s so easy to control. It cuts on the pull stroke. An English-style backsaw, of course, is just the opposite; it cuts on the push stroke. The dozuki saw blade is very thin and makes a much narrower kerf. The less wood you remove, the easier it is to guide the saw.

2. It’s easy to cut right on the line with a dozuki saw because its tempered blade stays extremely sharp for a very long time. Even if you miss the line, you can start over again a hair breadth’s away.

2. It’s easy to cut right on the line with a dozuki saw because its tempered blade stays extremely sharp for a very long time. Even if you miss the line, you can start over again a hair breadth’s away.

3. Cutting small parts is safe and easy with a dozuki saw. Dozukis are designed to make splinter-free crosscuts that are as smooth as glass. Make your own miter box to guide the cut.

3. Cutting small parts is safe and easy with a dozuki saw. Dozukis are designed to make splinter-free crosscuts that are as smooth as glass. Make your own miter box to guide the cut.

4. The teeth on most dozuki saws are designed for crosscutting. They have small, angled tips that score the wood like the blade of a knife. These teeth do a fine job with short rip cuts, such as dovetails, but some specialized dozuki saws have teeth designed primarily for ripping.

4. The teeth on most dozuki saws are designed for crosscutting. They have small, angled tips that score the wood like the blade of a knife. These teeth do a fine job with short rip cuts, such as dovetails, but some specialized dozuki saws have teeth designed primarily for ripping.

5. Most dozuki saws have replaceable blades. When your blade gets dull or damaged, just drop in another one. (Dozuki teeth are very hard, so it’s virtually impossible to sharpen them.) This blade rotates out of its stiffening spine when you tap it against a block of wood.

5. Most dozuki saws have replaceable blades. When your blade gets dull or damaged, just drop in another one. (Dozuki teeth are very hard, so it’s virtually impossible to sharpen them.) This blade rotates out of its stiffening spine when you tap it against a block of wood.

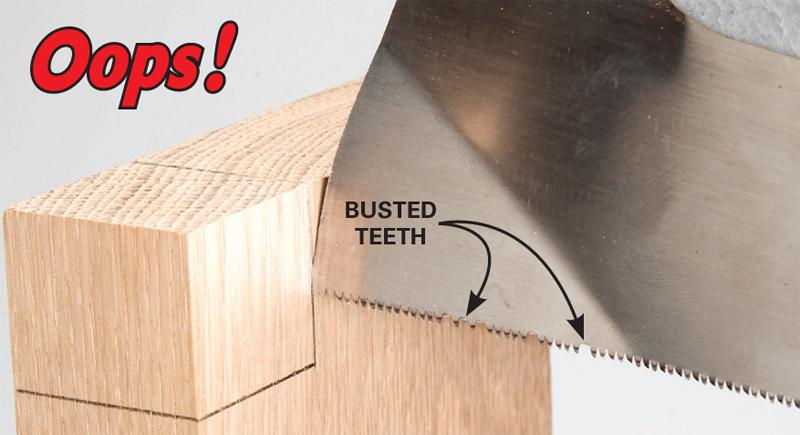

Oops!

Yup, this saw blade is history! I pulled too hard, and when the blade came out of the cut, I tried to push it right back in. Didn’t make it. The thin blade bent at an awful angle (not to mention the teeth I busted off earlier), and now it’s as useful as burnt toast for accurate cuts. I’ll save it for rough work. Dozuki saws take some getting used to. Mistakes like this (well, maybe not as bad) are common if you’re too impulsive. It’s a good thing these saws have replaceable blades!

Yup, this saw blade is history! I pulled too hard, and when the blade came out of the cut, I tried to push it right back in. Didn’t make it. The thin blade bent at an awful angle (not to mention the teeth I busted off earlier), and now it’s as useful as burnt toast for accurate cuts. I’ll save it for rough work. Dozuki saws take some getting used to. Mistakes like this (well, maybe not as bad) are common if you’re too impulsive. It’s a good thing these saws have replaceable blades!

Tips for using a Dozuki Saw

If you’re 10 years old and have never used any kind of handsaw before, learning to use a Japanese dozuki pull saw should be a breeze. For the rest of us, forget everything you know about saws. Dozukis are that different.First, you have to get used to cutting on the pull stroke. The trick to doing this may seem silly, but it’s very effective. Wear a blindfold. Don’t worry about following a line. Just feel the saw cut.Pull with your elbow, not your wrist. Steady the saw by locking your wrist in position.Don’t press down hard. Let the saw do the work. Dozuki saws cut so effortlessly that the weight of the saw itself is almost enough to get it through the cut. Pushing down too hard on a saw can make it bind or, in the worst case, break off some of the saw’s teeth. (A dozuki will work OK with a few missing teeth, however.) You can take off the blindfold now. Always start your cut on the far side of the workpiece (see photo, left). Take long strokes, but don’t pull the blade out of the cut. Short strokes invite more error. On crosscuts, tilt the blade up about 10 degrees. This is the ideal angle of attack for the blade’s teeth. Try sawing with two hands. Square yourself to the workpiece and pull the saw toward your belt buckle (see photo, bottom left). Put one hand in front of the other, or hold them side by side, as though you’re praying for a good cut. Your plea will be answered! This stance makes it easier to steady the saw and stay on a line, but it’s perfectly reasonable to stand to one side and saw Western-style.

Start your cut on the far side of the workpiece. Dozuki saws cut on the pull stroke, so this rip cut is actually going downhill, with the grain. Lean the workpiece toward you for a better angle.

Start your cut on the far side of the workpiece. Dozuki saws cut on the pull stroke, so this rip cut is actually going downhill, with the grain. Lean the workpiece toward you for a better angle.

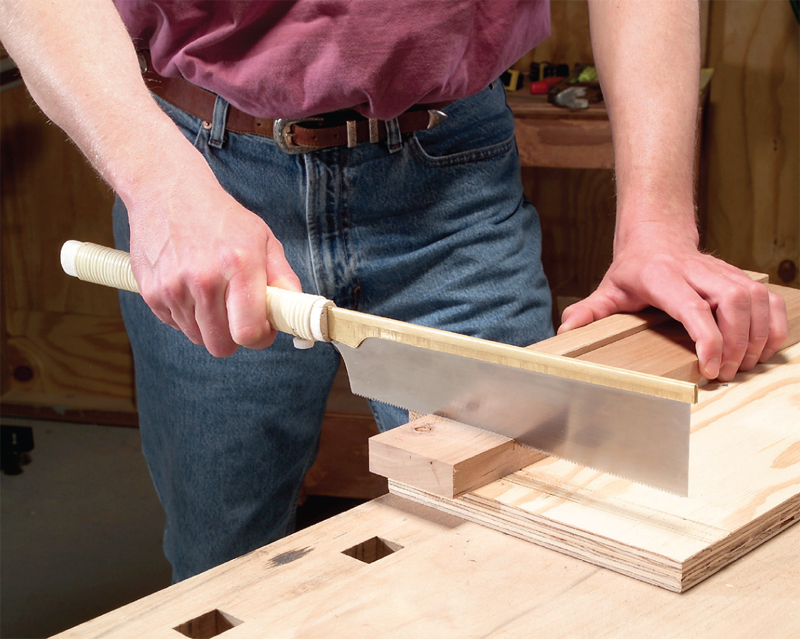

Hold your dozuki saw with two hands and pull it square to your body. Holding the saw with one hand, Western-style, works OK, but this method gives you even better control.

Hold your dozuki saw with two hands and pull it square to your body. Holding the saw with one hand, Western-style, works OK, but this method gives you even better control.

Recommendations

It’s hard to go wrong buying any dozuki saw because they’re all made to very high standards. Most go for $40 to $50. For most woodworkers, this is all the saw you’ll ever need. Dozuki saws are made in Japan, but we’ve identified each of our picks by the name of an American catalog, which often doesn’t specify the actual manufacturer. Lee Valley, leevalley.com, 800-871-8158, Steel-backed dozuki, 25 tpi, #60T55.01.If you’ve never used a Dozuki before, buy this one to learn on. It cuts nearly as well as saws costing twice as much. The blade isn’t replaceable and the handle isn’t wrapped with rattan, but that’s OK. It’s a good, basic saw. Japan Woodworker, japanwoodworker.com, 800-537-7820, Razor saw, #19.210.0, 26 tpi.This fine saw breaks down into two short pieces for easy storage.

Japan Woodworker, japanwoodworker.com, 800-537-7820, Razor saw, #19.210.0, 26 tpi.This fine saw breaks down into two short pieces for easy storage. Woodcraft, woodcraft.com, 800-225-1153, Dozuki Z saw, 26 tpi, #12F27.This is a terrific, general-purpose saw.

Woodcraft, woodcraft.com, 800-225-1153, Dozuki Z saw, 26 tpi, #12F27.This is a terrific, general-purpose saw.

Premium saws

Some dozuki saws are still handmade by Japanese artisans. The blades of handmade saws are not replaceable and must be sent to a master sharpener when they get dull. These saws start at about $100. Yes, that’s a lot of money, but not for a tool that’s the best in its class. It’s not just hype: Handmade saws are amazing tools. They’re so sharp that it’s very easy to follow a line. They cut extremely fast. With fewer strokes, there’s less chance you’ll wander off the cut. A handmade saw should not be your first dozuki, however. Learn to use an inexpensive saw first. They work so well that you may be perfectly content and never need another. Misugi Designs, misugidesigns.com, 707-422-0734, White steel rip-cut dozuki, 13 tpi.Expensive, yes, but cutting with this handmade saw is like driving a Porsche. It’s very easy to track on a line. The blade is not replaceable. It can be resharpened, but only by an expert. This story originally appeared in American Woodworker July 2004, issue #108.

This story originally appeared in American Woodworker July 2004, issue #108.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.