We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

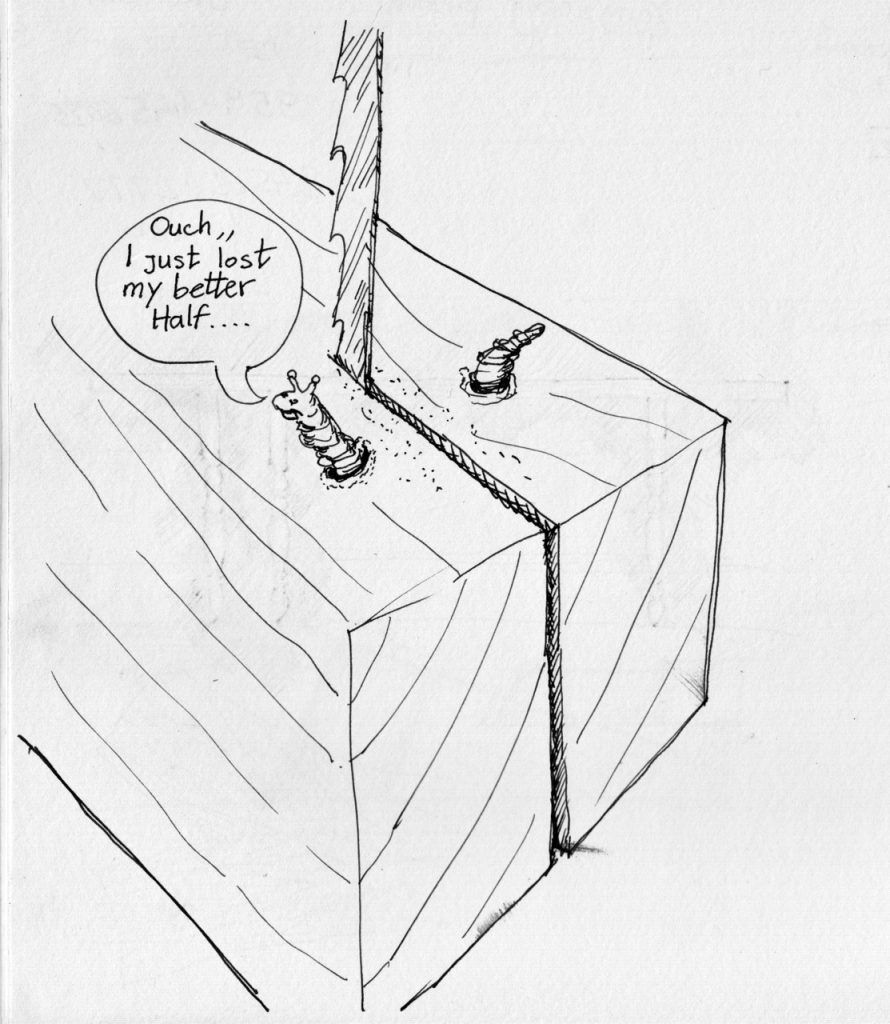

Ouch, I just lost my better half…

The structure and design of our waterfall coffee table was really simple, with only one truly original element – the front turned leg. The other leg as well as the tabletop, is a live edge slab mitered and reconnected in a 90 degree joint that is reinforced with domino keys.

Turning the Leg

I began by searching for an appropriate piece of hardwood. During a short visit to the area behind the shop I spotted an abandoned beam that seemed like it was made of walnut laying on top of a big pile of reclaimed wood. I have no idea if the beam was part of a timber frame building or a rejectee of the lumber industry, but it was there and looked promising.

The beam was wet and infested with some bugs. But that did not deter me as I knew that salvaged wood can look spectacular if you know what to do with it. In this case my plan was to saw the beam into blanks, turn one of them to wider than the intended dimensions, dry it in the microwave and finally re-turn it into my intended design.

The walnut beam that we salvaged was long enough to provide wood for a few projects, among which was the sycamore coffee table that my student Mark built. The beam was a home to a few wood borrowing insects. It also provided a shelter to a snake who slithered away once we lifted it from the pile.

After crosscutting and re-sawing the beam I checked its moisture content, which was high.

I turned the leg oversize, then I “baked” it in the microwave for five minutes at medium heat. I waited until the leg cooled down (that took surprisingly longer than anticipated), then I repeated the process a few more times that day until it measured dry enough. Once this was done I returned the leg to final dimensions.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.