We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

These are the lathe tools that I use. From front to back, they are: a 3/4″ roughing gouge; a 3/4″ spindle gouge; a 1/4″ “lady finger” gouge; a 1/2″ spindle gouge; 3/4″, 1/2″ and 1/4″ skews; a 1/2″ diamond point; and a 3/16″ parting tool.

When it comes to turned furniture components, you only have a few options. You can buy mass-produced factory-turned components that do not accurately recreate the fine details in period furniture; you can make friends with a turner; or you can invest in a lathe and turn your own. If you decide to go with the third option you’ll need some woodturning tools (in addition to your lathe). This can seem like a huge additional investment but you might not need quite as much as you think. In this excerpt from “Woodturning Techniques: Furniture & Cabinetmaking,” award-winning furniture maker Mike Dunbar explains which woodturning tools you’ll need.

Selecting Woodturning Tools

Most novice turners have two major misconceptions about lathe tools. First, someone who has not worked on the lathe imagines turning to be a herculean struggle between himself and the wood, in which he is required to be armed with hefty tools. Second, novice turners assume that in order to do a wide variety of turnings they need a wide variety of tools.

Tool catalogues reinforce the latter misconception by displaying a vast array of turning chisels. Just open a recent catalogue and you will note the mind-boggling selection of turning tools offered. Unless you know what you are looking at, you will quickly become confused.

There is one important point to bear in mind when pondering the vast selection of tools available. Many of the tools offered for sale will not be useful to you as long as you are turning between centers. For this reason, do not buy a great number of tools right away. Also, do not buy boxed sets of tools. These, too, will contain tools that you will not often need. In fact, once you have become more experienced on the lathe, you will be surprised at how few lathe tools you do use.

The following tools are useful for most beginners: a 3/4″ roughing gouge, a 3/4″ and a 1/4″ spindle (lady finger) gouge, a 1/2″ and a 3/4″ skew, and a 3/16″parting tool. A 1-1/4″ roughing gouge, a 1/2″ spindle gouge, and a 1/4″ skew can be bought later if you find that you need them.

Roughing Gouge

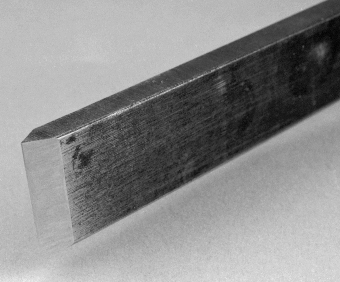

A roughing gouge is a heavy tool well suited for the fast removal of waste wood. It is a deep flute gouge that has its cutting edge ground straight across in the same manner as bench and carving gouges.

In use, a roughing gouge cuts a deep trough out of the corners of the spinning blank. At the same time, the cutting edge’s straight sides completely sever the chip, so there is little or no tearout from the surrounding wood. Although the roughing gouge is a very aggressive tool that cuts a thick chip, at the same time it keeps the process under control.

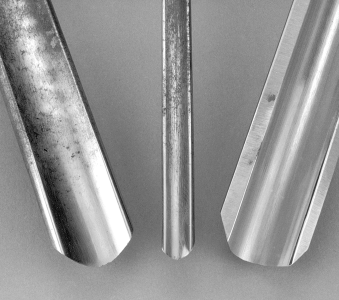

A roughing gouge’s cutting edge (right) is ground straight across, while the edges of spindle gouges (left and center) are rounded like your fingernails.

Spindle Gouge

Spindle gouges usually have lighter blades than roughing gouges and have standard flutes. Rather than being used to round the blank (although they can do this on light work), spindle gouges are used to shape the various elements that make up a turning. The round cutting edge is necessary, as the corners created by a straight edge could catch in the end grain when you are cutting coves and other concave shapes.

Skews

The skew is a flat chisel with dual bezels, one ground on each side of the wide blade. The skew is perhaps the most difficult turning tool to learn to use properly, but it is also the most versatile. The more accomplished the woodturner the more he relies on his skews for roughing, paring and planing (finishing).

Parting Tool

The parting tool also has two bezels, but they are ground on the blade’s narrow edges. This aligns the cutting edge with the thick rib running down the middle of the blade.

The parting tool is used for dividing a blank into segments (which are then shaped with other tools), for establishing depths, and for cutting pieces out of the lathe.

For more in depth information about woodturning tools as well as turning techniques, tool maintenance, safety and more check out Mike Dunbar’s “Woodturning Techniques: Furniture & Cabinetmaking,” available now at ShopWoodworking.com.

For more in depth information about woodturning tools as well as turning techniques, tool maintenance, safety and more check out Mike Dunbar’s “Woodturning Techniques: Furniture & Cabinetmaking,” available now at ShopWoodworking.com.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.