We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

This week, I swear I’m getting started on my workbench. To heck with my computer, I need to make dust or something. It’s time to get into the shop.

This week, I swear I’m getting started on my workbench. To heck with my computer, I need to make dust or something. It’s time to get into the shop.

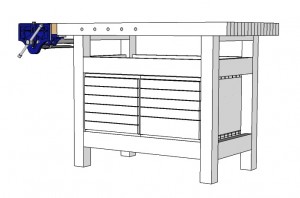

Trouble is, I don’t have, as of yet, any tools at the Popular Woodworking Magazine shop. I need a place to store my tools when I bring them here. Instead of building a bench first, I’m going to build the two boxes that make up my workbench storage. These boxes will eventually fit into my bench when it’s complete.

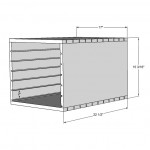

The sides, top and bottom are all 22 1/2″ wide on these boxes.  My first thought was to build them using Baltic-birch plywood, but I want to dovetail the corners for strength and plywood is not the best material when cutting dovetails. That has me thinking solid wood.

My first thought was to build them using Baltic-birch plywood, but I want to dovetail the corners for strength and plywood is not the best material when cutting dovetails. That has me thinking solid wood.

Another thing is that I plan to paint these boxes (and the base of my bench, too). Ordinarily, I would immediately turn to poplar, as I did with my Shaker Workbench from December 2007 (issue #166). But I’m thinking yellow pine. Why? I have some in stock (I would need to purchase poplar). Another reason I’m leaning toward pine is because things slide great on yellow pine.

When I built the Wright Shaker Counter in the June 2012 magazine (issue #197), I used yellow pine for the drawer boxes. That piece I kept for myself and I use it daily. The drawers slide in and out with the flick of a finger. That’s the way I want the drawers on my bench to slide. The problem is that I have not painted yellow pine. How does it paint? Does it hold up?

So the question I’m putting to you is this: Should I bag the dovetails and use plywood, dig into my checkbook and pay for the poplar or be thrifty and use the pine for a better slide? Leave a comment and let me know.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I guess that I must be from Missouri. All this discussion about using the wood that is “on hand” is great for certain things but I’d be concerned that it would be good for your steel tools. My grandfather was a carpenter /cabinetmaker and he always keep his tools in various wooden chest , boxes and drawers. He always used Eastern white pine (EWP) and his tools never, ever rusted while being stored. I think that its safe to say the the soft wood absorbed humidity in the air before it could condense on his tools. I have a box of his cast iron pipe wrenches that I inherited and when I open ita month ago all the pipe wrenches were as clean as a whistle with no rust. With all the resin in Southern yellow pine (SYP) and similarly plywood which is typically SYP with all its resins plus more resinous adhesives, I’d want to see that those woods protect steel as well as EWP or yellow poplar will.

Sometimes you need to buy wood for the task at hand. I’ve read countless article about how to control rust in the shop, and good softwood tools drawers and chests certainly do the trick.

I say Pine and if you want to see a little grain use some General Finishes Milk Paint and wax that baby.

Made a lot of drawers with 1/2 inch baltic ply using router template dovetails. They are as solid as the day I made them 15 years ago. I also like using the half blind tongue and rabbet from Tage Frid. Nothing wrong with plywood in this application.

I’m kind of in the same situation. I recently started rearranging my workbench area and it includes adding storage under the backbench where two Kennedy machinist tool chest once occupied. The backbench is made of 2×4’s with a ¾ in. particle board top and the void left by the tool chests is sizable and wrought with opportunity.

Though I have not put pen to paper yet (or more accurately hand to mouse) for the design the same question applies: What case and drawer material should I use?

One approach would be a down ‘n dirty set of drawers made from plywood. The plywood material could be somewhat expensive but the techniques I’d use would cut the time required to build considerably and result in a functional set of drawers. But I really do not like working with sheet goods and I’m not sure if the final product would be all that pleasing (both in appearance and in gratification).

So I’ve settled on solid wood. I’m not under a time crunch to get it done. But at the same time it does need done.

I was thinking of Aspen. It’s an easy wood to work, available and not that expensive. It also paints really well (I’ll use a black or dark blue milk paint). What I don’t know, and you bring up, is how the drawers will slide in Aspen. So does anyone have experience with Aspen and sliding drawers?

Best regards,

– Marty

The southern yellow pine available to you guys in the south is some of the best material to work with. Go for the pine!

Hey Glen,

I would use the pine. Milk paint works well on pine.

Tom

My thoughts say why not make a chest of drawers with a bench top on it. This will give you more storage space and the ability to add a door for power tools, or tool rolls for carving tools. I say Birch, for it wears better and paints great and it is cheaper then pine- well at least in the east coast. For I hate all that waste of space under the bench.

FR

I would never use plywood with dovetails. If you use plywood, you could go with the pockethole glue and screw. Quick, easy, and strong. If I am going to go through the time and effort to create dovetails, they would be in something that shows them off. Why go through all that effort to place the finished piece under a workbench? Better to strive for function than form.

Now I have an idea where to use the SYP boards which made up the crate for my tall case clock when I left SC.

Thanks, Glen.

Glen, I like the idea of the dovetails.The popular is a great wood to work with.It is a master at looking like several different kinds of wood.The plywood is ok to use but as you said no so good for dovetails and anyway why use it on something as important as a bench when there are so many other choices.If you are going to paint it anyway(Which I think it is a Sin to paint wood)You might as well use the plywood or something else like mdf.Who cares.You are painting it and covering up the beauty of the wood.Just my thought.

Yes, the knots will bleed. And pine will dent. It’s a workbench, does it really matter? Do you really need the strength of dovetails, or do you need to get it done, and spend the time on the bench?

I realize you are building for an audience and probably a customer base. And I know that Frank Klauz has an altar for a workbench. But if you look at older benches, they were built out of what was at hand, and used and beat up. I think we get a little too concerned about this stuff.

I guess what it comes down to is do you want to slowly build a bench, enjoy the process, and have a bench with the best appearance and maybe functionality, or do you just want to get to work?

I’m assuming that these boxes aren’t going to be moved much before the bench is built and once they are eventually located on the bench, probably never moved again within the shop, sooooo…Do you really need the strength of the dovetails? (Once it’s painted, nobody but you is going to know that they are or are not there unless you blog about it.) It’ll be quicker to build the boxes and then you have more time to build the bench. Unless you really want to practice dovetails, which I seriously doubt is the case, I’d go with the quicker solution.

Wood choice depends on the look you’re going for, but I’d bag the dovetails and use cut nails and glue. Cut nails would look kind of cool on a shaker style bench.

.

Yeller pine it is. Whip up the saw and router.

Dovetails are classy, plywood sucks and besides, you are a master at dovetails.

Yellow pine paints fine but any knots will bleed a little sap — even if you use primer to seal them.

Be thrifty, and get to work, you slacker!!