We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I’ve wanted to make a new mallet for a while now and at last found a bit of time to take the project forward. I knew I’d want to make a joiner’s mallet. This style is the classic type that has been typically found in a carpenter or joiner’s toolbox for many a long year. I like this setup because I’m used to the feel and did not want to change the muscle memory I’ve built up over time.

I raided the scrap bin and found a bit of ash for the handle and iroko for the head. Ash is a great timber for tool handles as it absorbs shocks and has a degree of flex. The head is iroko but for no other reason that it’s dense and was to hand.

I was tempted to copy my Narex mallet as it has served well and was nicely balanced – but a chance meeting at a car boot sale changed that. I got a few bargains; one of them was Jim Kingshott’s book “The Workshop” for the princely sum of £1. (On Amazon UK it’s available for £0.02 + shipping, so it’s a good value online, too.)

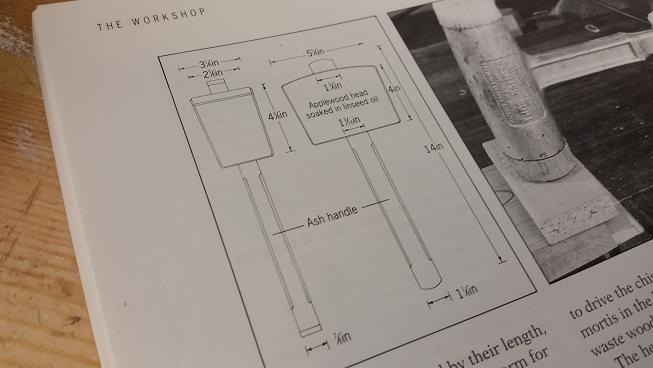

Mr. Kingshott has an enviable reputation among woodworkers so I knew this book would be a good read. The section on power tools is perhaps the only area that has moved on since the publication, but that aside, a great deal of other content is still spot on! Within his sage writings on hand tools he provides the details for a joiner’s mallet. It was very similar in proportion to the Narex but it had a nice splay to the edges of the head, and used the tapered handle to secure the joint at the head rather than the glued joint of the Narex. Mr. Kingshott calls for an apple head – but as mentioned above my brief was whatever was hanging around.

Construction is pretty simple as you’ll see in the video below. I don’t have many tips, but here’s one: Make the handle over length by a couple of inches. The reason for this is if your mortice ends up a little wider or narrower than it should, you can trim the handle accordingly or ease its edges. If you go for perfect and need to adjust, you might just waste that valuable ash handle. It’s one of those occasions where playing chicken does not slow you up any and makes working less risky. Apart from that, it a nice practice piece or a fun project on which to hone your mortice and tenon skills. I hope you enjoy the video and if you see one of Mr. Kingshott’s books consider picking it up; he has a legacy that’s worth discovering.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Sounds so familiar getting pieces and parts out of the scrap pile to make a mallet. I made two of which one went to a friend. They both were made with a hickory handle and a chunk of Osage orange that started out as a piece of firewood. Watching the pneumatic chisel at work just doesn’t get old.

Nice video (wish I could saw that quickly!!). I was intrigued by Mr. Kingshott’s book but I’m afraid the word is out! The US Amazon site shows pricing for the book at way above $25! Oh, well, I’ll just keep my eye out for it in the future. I do have a very similar mallet I picked up in a local antique store for the major price of $9 – cleaned up the head a bit and I’m off to the races. Still would love to make one and will some day. Not because I need it but, well, just because it’s neat!

Ditto on Mr. Kingshott’s books. His are EXCELLENT resources.

What is the Angle of the face?

Nice looking mallet!!