We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

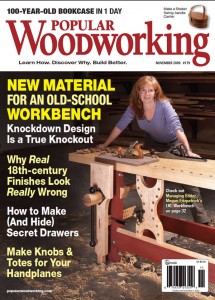

I get more questions about workbenches than any other – and among those, many of them are about the LVL (Laminated Veneer Lumber) bench Christopher Schwarz and I built in 2009, that appeared in the November issue.

I get more questions about workbenches than any other – and among those, many of them are about the LVL (Laminated Veneer Lumber) bench Christopher Schwarz and I built in 2009, that appeared in the November issue.

After more than five years in use, the top remains dead flat. It has a few dings from chisels and the like, but it had not needed flattening. in contrast, my pine “roubo” bench at home that is three or so years old has been flattened four times (and is due for another session).

The base? Well, I’d recommend southern yellow pine or some other kind of affordable “real” wood; the LVL compresses (as it’s designed to do), and that means the top has been pushed off the base by the pressure of the leg vise. I’ve added a bullet into the top of the front left leg and into the underside of the top, and that helped for a little while, but…now I just use a shim to make up the difference – an easy if somewhat vexing fix.

That said, the thing is heavy as all get out and has performed well for me. I love the sliding “deadwoman,” leg vise and quick-release tail vise, and I use this bench every day at work. Someday, if I ever get some free time, I’ll likely rebuild the base from SYP, using the same knock-down design.

Or maybe I’ll just build another bench altogether. I still have about 18 to go to catch up with Schwarz.

But, with the change in base material, this is absolutely a bench I’d recommend. So here are the plans, free. Happy Hanukkah, Merry Christmas, Happy Kwanza ,Merry Festivus, Happy Wednesday night.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I have been designing a bench in my head for six months now and am getting ready to tackle it this spring (workshop is in garage and its too cold out there right now). LVL is rather expensive here and SPL is not readily available. I am considering using another manufactured wood product called TimberStrand by Weyerhaeuser. Right now I am waiting for a piece of it to experiment on but am curious if you or others at PW have run across it. Around here it is about half the cost of LVL.

THANKS for a GREAT magazine and web site.

I built an LVL ‘hybrid’ this year with a doug fir frame. What a wonderful design – easy to build, solid as a rock, and looks great too. A very nice compromise for those of us for whom a monolithic workbench is not practical, or who live outside the yellow pine zone!

Love that bench and especially the vid of thee hopping up on top of it. Hope you had a great Christmas. Thanks for the plans.

What are the dimensions needed for the rough cut LVL material? 2×12’s are mentioned, but it doesn’t mention how many are needed or any other sizes needed.

Thanks!

What quantities and dimensions of rough cut materials for the LVL is needed? I saw it mentioning 2×12’s were ripped to use for the top, but it didn’t say how many of those were needed or any other sizes needed for the legs and stretchers. Any help, please