We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

As I conclude this intro into marking knives and how to wield them, I wish to show you three knives that I recently began using. Two of them have the potential to become your all-around shop knife on top of serving as a good marking knife. These knives are so inexpensive and yet are made to such great quality that it is just mind boggling.

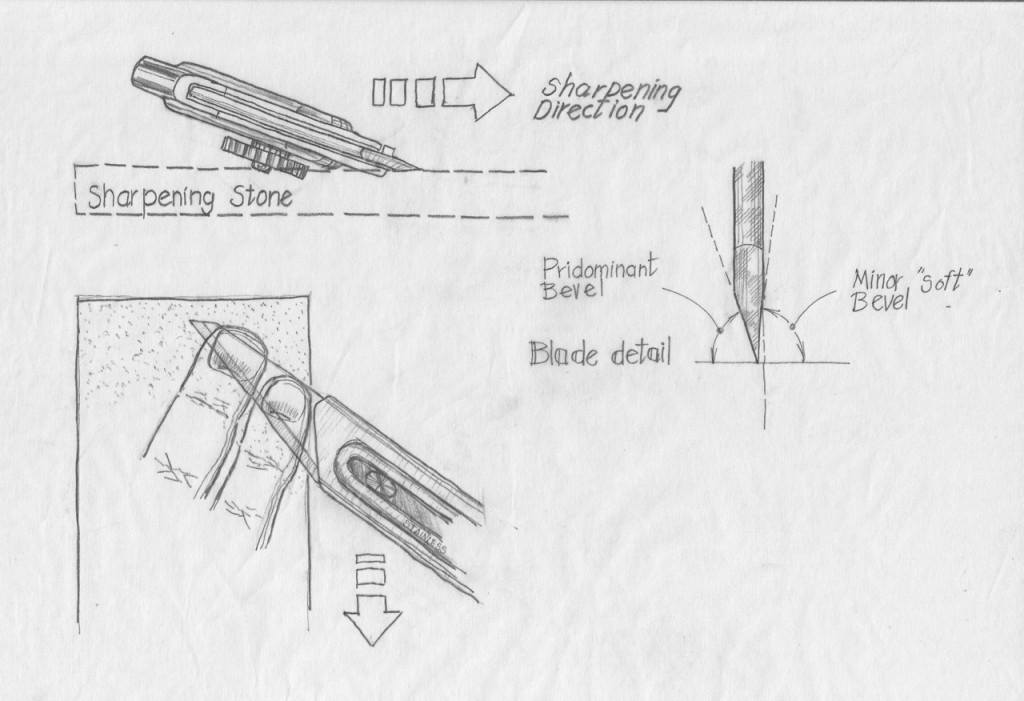

The two knives I am talking about are the Olfa 26B and 34B. Both are made in Japan, have a steel body and a retractable blade. The retractable blade can be an advantage for two reasons: blade and user protection when not in use, and protrusion versatility for dedicated use in a variety of cutting situations. The smaller of the two, the Olfa 26B, has a double-edged blade enabling you to rotate the blade from dull edge to sharp edge before resorting to resharpening. The Olfa Craft Knife L size 34B has a stainless steel body and a long single-bevel skewed blade and, like his smaller brother (the 26B), its blade locking mechanism is made of a knurled nut and a brass screw. Both knives have a predominant right-hand bevel and an unusual “soft” bevel on the left side that is almost untraceable. I have no idea why the maker chose to do that as this soft, insignificant bevel was a bit of a nuisance during honing becaise I had to pivot up that side in order to break the burr. A uniform flat back would have bestowed the blade with a more friendly geometry for sharpening/honing, but at a price of $6.11 (including shipping!) one can’t complain too much. The 26B is even cheaper ($4.11 including shipping, as of June 2015). So at these prices, roughly two cups of coffee (coffee shop coffee, not gas station coffee), why not get both… and no, I don’t have a stake, a royalty agreement or promotional contract with either Amazon or Olfa.

BTW, both knifes can be used for all kind of chores around the shop, from letter craving to opening cardboard boxes.

The third is a folding-blade, parallel-edge knife by Stanley, model 10-049. The knife’s body is made of die-cast zinc, which covers the blade for protection during travel and storage. The blade has two bevels and is easy to sharpen, but its folding hinge joint is a little loose. I found that the knife’s greatest advantage is the blade’s proportions – narrow and long – which can be convenient while marking in tight situations. Unlike the Olfa knives that have a right-leaning bevel, the Stanley has a bevel on each side – which is great if you are a lefty.

Sharpening a Double-bevel, Parallel Blade Such as a Utility knife or the Stanley

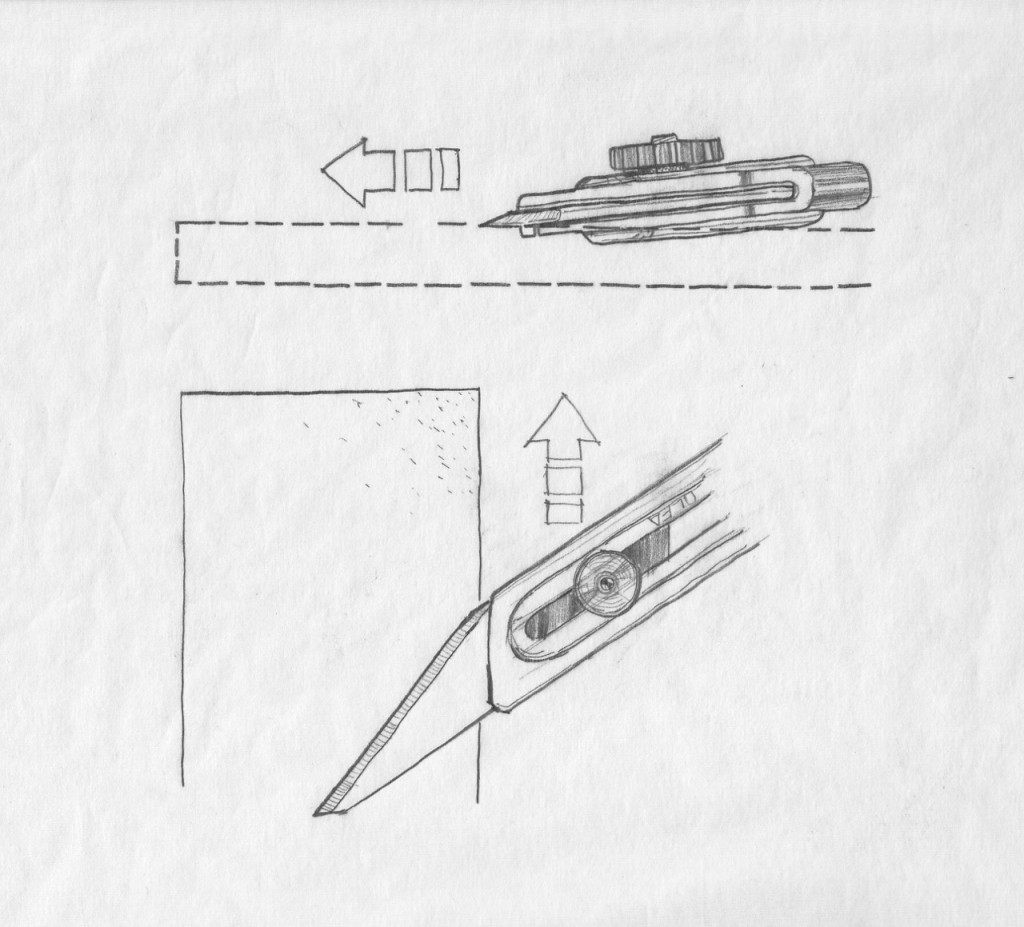

No matter what knife you choose, you will have to learn how to sharpen it, and most likely you will do it without the support of a jig. Learning to sharpen and hone freehand is an indispensable skill. It is performed in almost the same way a kitchen knife is sharpened on a flat stone. Keep the blade at 15-20° to the stone, or at an angle where the bevel is placed flush with the sharpening medium. Next, pass the blade a few times back and forth on the stone. Flip it over and repeat the same procedure on the other bevel. Progress to the next grit, repeat the above and most likely you will not have to deal with a folded burr. I like to begin sharpening on a #600-grit stone and finish honing my utility blades on #1,200-grit diamond stones.

How to Sharpen the Olfa Right-hand Skew-bevel Knives

Begin by placing the main bevel flush on the face of the stone then pass the blade a few times back and forth. I find it helpful to apply some finger pressure on the longer blade of the Olfa 34B as I pass it up and down the stone. Lift up the knife and feel the backside of the blade for the formation of a burr. Repeat the above until a burr is formed. Progress to a finer stone and don’t worry about breaking the burr at this point. Once you finish honing on your finest stone, turn the blade over to the backside, place it on the stone and pivot the blade upward until the soft bevel (that I mentioned before) is flush with the surface. Now push the blade forward to break the burr (Use some mild finger pressure on the blade as before). You can finish up the honing with a strop but remember never to push the edge into the leather. You should always pull it backward.

P.S. I take it for granted that our readers are not fans of the throw away culture and will sharpen their blades until there is hardly any tempered steel left on them. But just in case you are not, or if you are in the middle of a project and don’t have the time to sharpen, know that there are replacement blades you can get for all the knives I showed above.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

The blade for the 26B looks like it can be flipped for left handers. Can it?