We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

If a leg vise has a disadvantage – and I’m not quite willing to admit that it does – it would be its parallel guide.

The parallel guide is a strip of wood at the bottom of the leg vise that prevents the vise’s chop from spinning like a propeller. It also creates the vise’s leverage and makes it pinch your work right at the top of the chop. However, to do its job the parallel guide requires that you move its pin when you want to hold really thin stock or really thick.

And moving that pin is something that would-be bench builders don’t like. They always say something like: I want a leg vise, but I don’t want to stoop all day moving that pin.

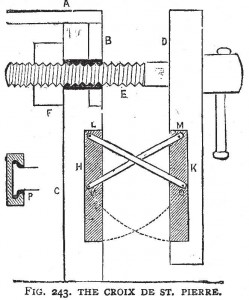

If you are one of those anti-stooping skeptics, then you should take a close look at the photos, drawings and video in this blog post. The St. Peter’s Cross (sometimes called “Croix de St. Pierre”), eliminates the parallel guide and the pin and the stooping. I first wrote about this bench accessory in my 2007 book “Workbenches: From Design and Theory to Construction and Use” and showed a drawing of one from the old book “The Amateur Carpenter and Builder” (Ward, Lock & Co.).

Lots of readers have asked about the cross in the last five years. Some asked: How does it work? Does it really work? It doesn’t really work, does it? Why would you discuss something that doesn’t work? But most readers asked: Where can I get one?

Here are the answers: It works like scissors. Yes. No, it works. Because it works. Benchcrafted.

Yup, soon the bench geniuses at Benchcrafted will be offering a cast St. Peter’s Cross that you can install on your workbench and eliminate the parallel guide and pin and stooping. Jameel Abraham and his brother, Father John, brought an oversized prototype of the hardware to the Lie-Nielsen Hand Tool Event in Chicago to show off. They had it paired with their Glide leg vise hardware, and the action was nothing short of magnificent.

Jameel says they are working with a patternmaker now to make the patterns for castings and they hope to begin offering it by the end of the year. No firm word on pricing. But it will be easy to install on any leg vise, either new or as a retrofit.

I ordered one so I can install it on the Roubo bench I built in 2005.

There are a lot of interesting details to discuss about this hardware. How is it best attached? Where did its name come from? Is it a French innovation? Can you make one from wood or lawnmower blades? But I have to get to the second day of the show right now.

So stay tuned this week for more entries on St. Peter’s Cross.

— Christopher Schwarz

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Oddly-named cross. It reminds me more of St. Andrew’s cross than St. Peter’s. St Andrew’s cross (also called a Saltire) is x-shaped, is the flag of Scotland, and makes up the white on blue cross in the Union Jack.

Bit of pointless trivia, I’m sure 🙂

I made a St. Peters’ Cross for my Roubo leg vice and it doesn’t stay parallel (which is its main purpose), when engaging the workpiece. the bottom part of the vice continues to move inward. Full details are on my blog site. Any suggestions will be appreciated.

http://www.youtube.com/watch?v=uyTRxNYE874 A short video on YouTube. The video is sideways so look to the right of the picture to see the bottom going out of parallel.

http://awalkinthewoods-woodworking.blogspot.com/

Here is vice that I picked up from a want ad, Just needs some new wood and put back to work.

http://www.picturetrail.com/sfx/album/view/24103650

I noticed that the chop in the first picture of this vise had something attached to it. Is it to prevent slippage and what is it? The reason I ask is that I have built a leg vise based on the LVL bench by Christopher Schwarz and have had some slipping problems. The chop is made from maple and it butts against maple on the bench and it slips more than it should.

Forgive my dim-ness, but what is the advantage of a leg vise like this over a basic face vise? I assume it is the distance from the screw to the top of the jaw, or is there some extra leverage applied by going down to the floor?

The boys of Wood Talk Online (Marc, Matt and Shannon) discussed this vise in Episode 96. I believe it was Shannon that mentioned there may be a trade off with this vise in that you can’t put stock under the screw in the way you could with the traditional vise. Other than that, I think they covered it very well and were complimentary to both vises.

I have their sliding tail vise installed on my personal bench and I love it, but wasn’t able to use their leg vise since the Nodin adjustable leg hardware makes difficult if not impossible to incorporate. I’m thinking though that with this scissor design I may be able to make it work, possibly by making the bottom attachment a quick release bolt for when I want to change the bench height from other than it’s normal height position. What think Ye ?

It may not make much difference, but you’re going to lose some clamping power compared to the parallel guide.

With the parallel guide the pin at the bottom gives you a long lever arm, for maybe a 2:1 mechanical advantage. (10lbs of pressure at the screw gives 20lbs of pressure at the jaws)

With the cross, the effective lever arm is the distance to the pivot point of the cross, giving a reduced mechanical advantage (and interestingly, the amount of reduction varies depending on how wide the vise is opened.

In practice it may not matter much though.

What a great vise. I’ve never seen on like this. This would be a great topic for an article in the next issue of PW.

Great LN show in Chicago. That bench leg vise w/cross looks like a great addition.

Thanks Chris, Megan, and the vendors for all the great discussions and demos. And of course, Jeff Miller for hosting. It was well worth the trip.

I can see how the scissor action of the cross and how its attached eliminates the pin in the traditional leg vise, however when you do this, don’t you lose all the extra clamping force generated by the pivot point of the pin being so low (one of the strengths of the leg vise)? With a vise like this it would seem the screw alone is doing all of the clamping, and what your left with is a face vise disguised as a leg vise?

Dumb question #612 …

How does this mechanism assist when using the leg-vise to hold very large objects like a door? The cross would get in the way… or would one only need the two inches or so of clamping surface that is present on each side of the cross?

If you take a look at the image at the bottom of this blog post, you’ll see a well used vise with this mechanism.

http://toolemerablog.typepad.com/toolemera/2009/09/we-all-have-our-vises.html

I don’t remember where I found the image so I can’t say anything more about it. You can see the bars look cast and manufactured.

Very cool!

I sent you a link to that picture last year when I first saw it and suggested the guys at benchcrafted might be interested in it. You’ve got me wondering if you passed it along.

Andrew

Wow, the Hovarter vise looks like a beautiful piece of work — it’s amazing the level of craftsmanship going on to support hand woodwork today.

Len Hovarter’s leg vise seems to be a cleaner and simpler solution for a leg vise — no spinning in & out for adjustment and plenty of clamping force.

Perhaps it’s just me, but the configuration shown does not look like it offers much jaw height above the screw. Not sure if that is a design limitation, or can be user defined. And yes, I’m sure this will be a very premium product, like north of $500.

Schweeeeet! Years ago I bought an old wooden vise screw at auction. Big deal? Well, the real reason I latched onto the shabby old dog was because it still had the leg vise attached ALONG WITH a wooden version of the St. Peter’s cross. So if anyone out there lusts for such a thing and might bemoan the expense of a cast piece, take heart, it can be made out of wood and work like a charm. I have proof.

I also just nailed down a nice little antique vise with a cast version of the cross too. Gotta love eBay.

Zackdog’s comment struck a chord with me — what about just mounting the Veritas or LN twin screw vise hardware vertically as a leg vise? Seems that might solve the parallel guide challenge.

Just curious Chris, why didn’t you discuss Lie-Nielsen’s new version of their leg vise last summer when they started using a chain-driven, double screw arrangement?

I happened to get their first one and it works great.

For some reason, L-N doesn’t really advertise it in their Roubo description, but it’s visible in their leg vise close-up photo. They also don’t list it with their other workbench hardware, but I’d bet that it’s available for purchase.

I believe it’s called a St Peter’s Cross because the Roman’s executed St Peter by nailing him to a cross shaped like an X. Possible upside down if memory serves.

IT’S FINALLY TRUE!!!!!! AHHHHH!!!!

I just came in for dinner after drilling the hole in the leg for the Benchcrafted glide vise. My plan was go back out and make the mortise in the leg for the parallel glide. After reading Chris’ post, I’ve decide to make a St. Peter’s Cross and install it instead. I believe the Benchcrafted one will be wonderful, but I’m confident I can make one cheaply install it without issue.

SWEET FANCY MOSES!!!!

My guess is that the writers (Ward, Lock & Co.) confused croix de Saint-Pierre with croix de Saint-André, still very present in Google image. Surprisingly as the cross of St Andrew is also part of the Scotish flag and the Union Jack.

By “…oversized prototype…”, are you referring to the height of the prototype above the bench top only, or additionally the size of the hardware itself?

It would be nice if Benchcrafted could also offer a retrofit kit, comprised of the “cross” or “scissors” pieces and some instructions, for those who already have the Benchcrafted Roubo leg vise hardware installed with the parallel guide. From what I’ve seen, most of the vise chops and bench legs, look thick enough to accommodate a long mortise for installation.

Wow, very impressive! Judging by the current price of the Glide, I imagine this setup will be out of my price range for some time.

Watching the video did get me wondering about vertically mounting a twin screw vise to obtain a similar effect. To your knowledge, has anyone tried installing one in this manner?

Thanks for posting the video,

Gene

Wonderful!!! I might be missing something but why not use the proper size and thickness angle iron stock (with the correct additional parts top and bottom) instead of a casting?