We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

When Egyptian King Tutankhamun was buried in haste, the linen cloth he was wrapped in was soaked with linseed oil. And, perhaps because Tut was buried in haste, the oil was not allowed to cure.

And so began one of the most common safety messages in relation to finishing: Spread out your oily rags to dry cure to avoid spontaneous combustion.

Yup. The oily rags that wrapped Tut’s body spontaneously combusted, charring the body that Howard Carter discovered in 1922. You can read all about that event here.

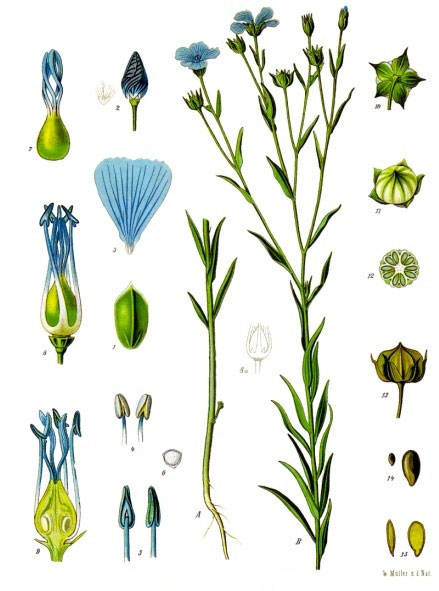

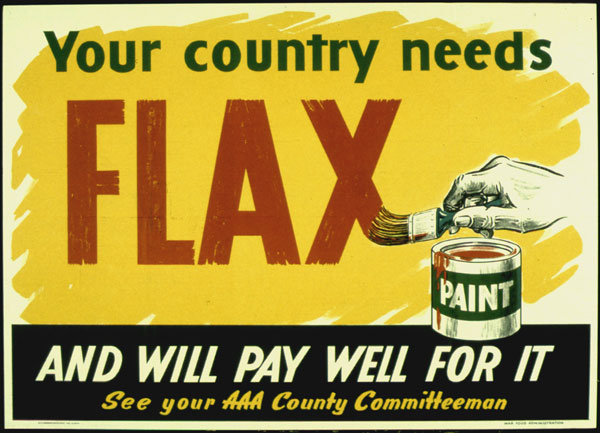

This week I’m adding multiple thin coats of linseed oil to the oak aumbry I’ve built for an upcoming issue of Popular Woodworking Magazine, and in between coats of finish I’ve been getting in touch with my inner Linum usitatissimum. The flax plant has a long history with humans and their woodworking. One of the earliest domesticated plants, flax has long been exploited for its fibrous stalk and seeds.

In some parts of Europe its oil is used as a hearty flavoring to bland foods. But here in the United States, we use flax far more as a cloth – it is linen – and as an important component in finishing. It is the basic ingredient in oil paints and many other finishing products, most notably boiled linseed oil.

Plain linseed oil is a drying oil, meaning it will stiffen and dry when exposed to oxygen. But it takes a long time for this to happen – it can be days, depending on the ambient temperature. And so historically linseed oil was heated – sometimes with lead – to significantly shorten its drying time. Today linseed oil is transformed into “boiled linseed oil” by adding metallic dryers.

Stephen A. Shepherd discusses how you can make your own boiled linseed oil at home (with some precautions) so you can avoid contact with metallic dryers. Details are in “Shellac, Linseed Oil, & Paint” (Full Chisel), which is available through his web site. The book is an interesting read.

I haven’t tried it, and so I use the off-the-rack “boiled linseed oil” from the home center and wear gloves when applying it.

As a stand-alone finish, linseed oil is an adequate finish, as long as you know its limitations.

Many beginning woodworkers use an oil-only finish because it is easy to apply and gives a nice low-lustre sheen. The main problem with linseed oil is that it doesn’t offer much protection against scratches or water. You can get around this problem by applying many, many thin coats of oil, like gunsmiths do, but this is time-consuming.

The other problem with a straight oil finish is that unless you apply many coats, the finish will lose its lustre in short order. So you have to wax the finish (and maintain that) or add more oil. I’ve seen many pieces of furniture from beginners that suffer from this problem – the wood looks dull, lifeless and like it is covered in a fine layer of dust.

Despite these limitations, I use boiled linseed oil a lot. It is a fantastic base coat for many projects because it will help accentuate the figure in the wood and will yellow over time (some people don’t like the yellowing; I do).

However, after applying the oil, I follow it up with something else that will add some protection.

If you don’t own special finishing equipment (such as a spray gun), I recommend you make your own topcoat finish from readily available sources. I use a finish that is equal parts spar varnish, boiled linseed oil and “odorless” mineral spirits.

Just mix them up in a jar and you have a near-perfect wipe-on finish. Apply thin coats (I usually use three coats) and this finish will add enough protection for typical furniture. It also will prevent the straight oil below from drying out. I wouldn’t use this finish on a kitchen table, for example, unless I added a lot of coats.

Of course, when you finish with your finishing, you need to dispose of your rags properly so you don’t burn your tomb down. I usually spread the rags out flat outside or temporarily on the edge of the garbage can until I can get them outside.

If you need the rag for the next coat of finish, you can seal it in a Ziploc bag with all the air removed. That will keep it moist.

I’ll be honest, I’ve never had a problem with the rags heating up, even when I intentionally tried to start a fire. Last year I soaked a bunch of rags and put them in a tin can outside to see how long it would take to start a fire. No joy.

Oh well.

— Christopher Schwarz

If you are beginning finisher, I can offer no higher recommendation than Bob Flexner’s “Wood Finishing 101.” It is short, easy to understand and 100 percent free of misinformation. This book is only $12.50, but it’s worth its weight in gold.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Hi Chris I loved the Anarchist’s Tool Chest. Now to my question, I have “Inherited” a front door from my father-in-law , it is in serous need of a refinish. The last time he did the refinish was just a few years ago with Val-spar high gloss. There is a full glass storm door in front of the wood door and now the finish has peeled and flaked, maybe from too much UV? Would the linseed oil be a good replacement or the Tung oil mentioned above? I am at wits end as it looks horrible and we just painted the home so now the wife wants a “pretty” door… When you finish laughing a reply would be greatly appreciated. Thanks again and keep writing.

Watch out with the rags in a bag. I’d always heard about the oily rags cautions and thought

after 50 some years I must be within reasonably safe practices. UNTIL .. a semiannual re-coat on the deck. “Rosewood Oil” is what they call it. Used Cotton rags go into a black plastic bag and twist tied. That was on a Friday waiting for trash day on Monday. This is all outdoors. I never would have considered the same inside. Then on Sunday morning, on the other side of the house, watching the dog do her thing. I got a very, very lite sniff of oily smoke. Admittedly, my cognitive switch wasn’t on till a few hours later. Yep… there it was, in the middle of my patio. The heat had melted some of the bag. Not a fire yet but enough to impress me of the dangers I’ve heard of so many times. Somewhere I remember a TV spot where a pile of rags explodes. This was so dramatized that I knew not to pile oily rags and I thought I got the point.

Now all rags go outside and no plastic bags for me. My dog saved me again!

I have been using boiled linseed oil for years to recoat outdoor implement handles. I know that it is not very durable but it is quick. What exactly is Tru-Oil by Birchwood Casey? Is it any good?

Trying to intentionally start a fire by “put(ting) them in a tin can outside to see how long it would take to start a fire.” Doing this experiment outside where the vapors might not accumulate and in a tin can which will help conduct and dissipate the heat are no reason to discount the risk. I think boiled linseed is a great finish on its own and also as part a more complicated process, but please don’t downplay the need to handle the material with real caution. A quick web search an NFPA report (they write the national fire codes) that estimates an average 14,070 fires a year between 2005-2009 attributable to spontaneous combustion/chemical reaction. There is no way to tease out the oil or paint,but:

“In home structure fires (homes are defined as one- and two-family homes, apartments, and manufactured housing), the garage was the most common area of origin (20% of fires) and oily rags were the most common item first ignited (35%). Abandoned materials were cited as a factor in 34% of home fires, and improper containers or storage was a factor in 33%”

I have been using line-seed- oil oil for ages, mostly on spruce and pine for buildings and furniture.

This is the most important lessons.

Use raw (unboiled) oil to impregnate. It does not create a surface and penetrates deeper thanks to its smaller molecular size.

Use boiled oil to to create a surface.

Quality is very important. Cheap oil creates never ending troubles. It must be chemically neutralized, filtered and aged at least 6 month. It might be expensive but it is the only oil that gives an acceptable result.

Anders (Sweden)

Chris,

This is very helpful. Thanks. I think my past problems with boiled linseed oil had to do with not waiting long enough between coats. I have had decent results with a similar mix of spar varnish, mineral spirits and tung oil. Is there an advantage to using boiled linseed oil over tung oil? I remember reading that Nakashima was using tung oil on those big beautiful slabs and then I read that Maloof was using linseed oil. After I made a mess of a gorgeous piece of wood with linseed oil I figured Maloof was slipping something that didn’t belong into his stated recipe like my Italian grandmother used to do if you asked about the meatball recipe. It’s a form of copyright protection. But it was probably just my impatience.

Thanks as always for the interesting blog. What do you recommend as a go-to finish for those of us who DO have a spray gun?

In the Rumplestilskin story the pricess must spin straw into gold so she was making linen thread. I believe Sleeping Beauty also pricked her finger at a spinning wheel so she was probably also spinning flax.

Linoleum is making a comeback as “green” flooring.

Fine papers such as for bank notes and rolling papers are made from flax.

The final process in preparing flax for spinning is called “Heckling”, we’ve all been there!

Green Bay Preble HS did not start school with the rest of the school district this year. A couple weeks before school began rags spontaneously combusted, starting a fire which caused considerable damage. The fire began in an area where work was being done, and cameras caught the initial fire beginning.

Chris, how long do you wait between coats with the mix you mentioned?

The classic 1 part linseed oil, 2 part varnish, 3 part turpentine, with 2 cap full of japan drier is one of the classic old finishes. It is amazing how great it works and how durable it is as a finish.