We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

In 1991, I began wondering why backyard decks weren’t typically built better. Looking at them back then with my woodworker’s eye, there seemed so much that could be done to improve the lifespan and beauty of decks, yet somehow these details never happened. That’s why I began developing, testing and building my own collection of deck construction details based on how I saw decks fail and what I’d learned as a cabinetmaker about making wood beautiful. People started commenting on my deck construction and wanted to know more. This interest turned into magazine articles, videos, blog posts and finally something called How to Build a Great Deck. It’s a hands-on, video-enhanced deck design and construction course I created to teach three main things: how to build a deck so it lasts twice as long as usual; how to apply “furniture-grade” details to your deck; and how to choose deck finishing strategies that won’t drive you crazy.

In 1991, I began wondering why backyard decks weren’t typically built better. Looking at them back then with my woodworker’s eye, there seemed so much that could be done to improve the lifespan and beauty of decks, yet somehow these details never happened. That’s why I began developing, testing and building my own collection of deck construction details based on how I saw decks fail and what I’d learned as a cabinetmaker about making wood beautiful. People started commenting on my deck construction and wanted to know more. This interest turned into magazine articles, videos, blog posts and finally something called How to Build a Great Deck. It’s a hands-on, video-enhanced deck design and construction course I created to teach three main things: how to build a deck so it lasts twice as long as usual; how to apply “furniture-grade” details to your deck; and how to choose deck finishing strategies that won’t drive you crazy.

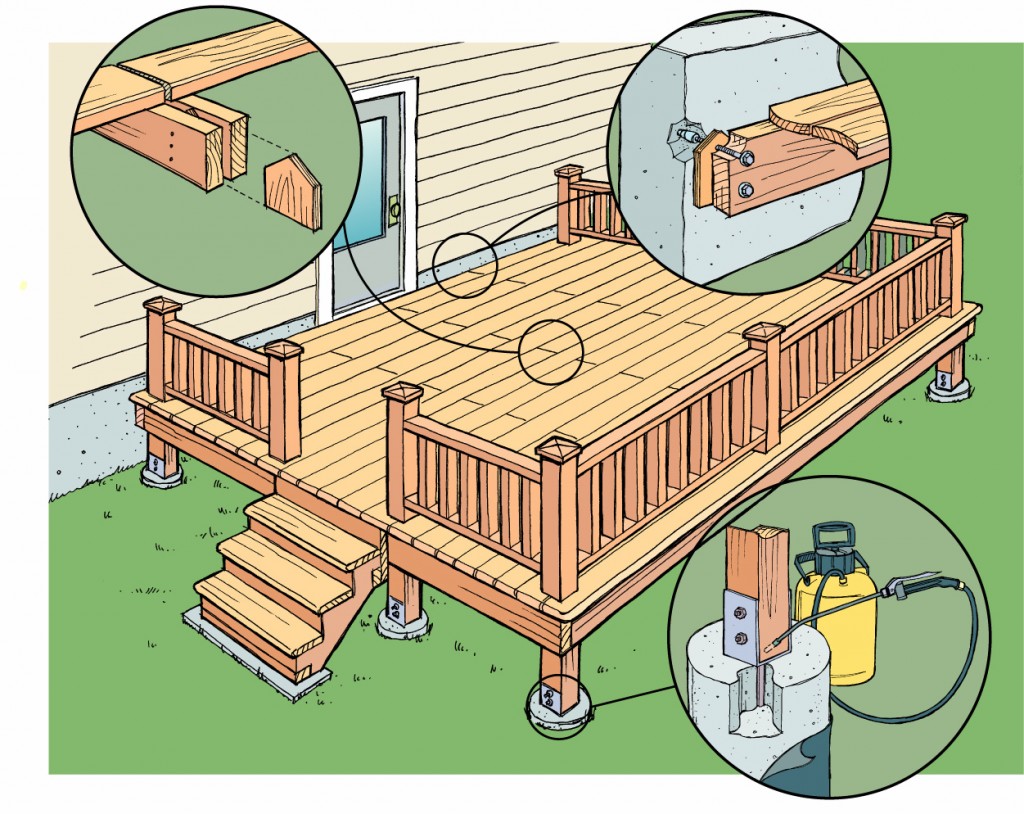

Just because you build a deck with cedar or pressure-treated lumber doesn’t mean rot won’t cut deck life short. How you build determines deck life just as much as what you build with. The durability features I’ve discovered minimize wood-to-wood contact zones so wood dries faster between rains. Dry wood is much less likely to rot, and you can apply this approach to any size or shape of deck. It doesn’t cost a whole lot more than regular construction, either.

Decks hardly ever have routers used on them, but there are lots of reasons to change that. Bullnose edges on deck board overhangs; big chamfers on pyramid-topped posts; routed deck board edges; mortise and tenon deck rail joinery. It’s amazing how impressed people are when details that are common in the wood shop make their way into a backyard deck.

When it comes to both old decks and new ones, I often hear from people who’ve had deck finishes go wrong. Peeling is usually the problem, but so is discolouration and mold growth. This is why I started a deck finish testing program at my shop 25 years ago. I now know from experience that many deck finishes fail after a year or less, no matter how carefully you put them on. The ideal finishing option for any wooden deck depends on your expectations and the level of ongoing maintenance you want to commit to. And of course, you also need to use finishing products with a proven track record, too. All my latest discoveries are in How to Build a Great Deck.

Decks are a great way to enjoy more outdoor living at your home, and as woodworkers we can do better than average building and maintaining a deck. Bring the same care, attention to detail and tools you normally use in the shop and your deck will look so much better for it.

Check out Steve’s Popular Woodworking University course, How to Build a Great Deck, to learn how to design and build your own deck.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

How to build a deck? What’s next, how to install a bathroom vanity or perhaps tips on growing tomatoes? I’m disappointed.

This is an ad for a basic carpentry article for homeowners. It doesn’t even have a passing relationship to woodworking.

Perhaps disguising an advertisement as a woodworking article is not a great strategy.